The new dimension of slicing

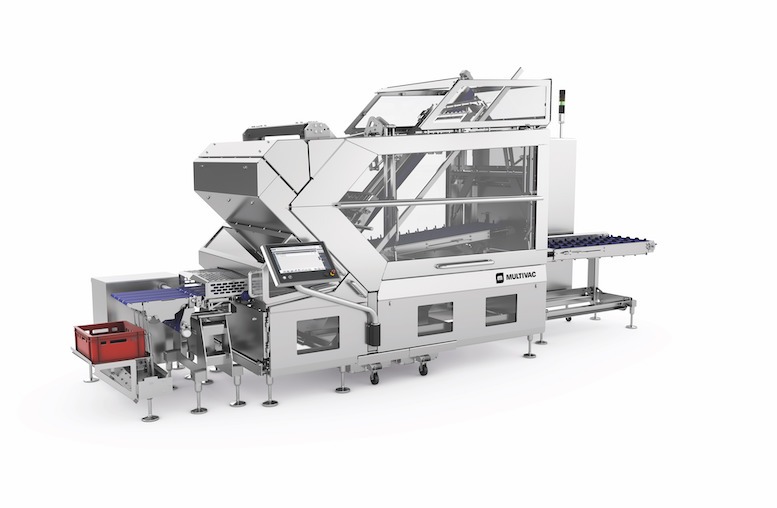

The SLX 2000 is the first of a new, forward-looking generation of MULTIVAC cutting machines. The high-performance slicer, which sets new standards on the market in many respects, will be presented to the public for the first time at the interpack in Düsseldorf (Hall 5, Stand A23).

Sustainability: outstanding cutting results and strong performance

Depending on the product in question, the high-performance SLX 2000 slicer, which can be configured for up to four lanes, achieves an extremely high cutting speed. Sausage, ham, cheese and vegan products with a maximum length of up to 1.600 mm are optimally sliced and placed on the portioning unit in a way that is gentle on the product, even at warmer temperatures. Sophisticated technology ensures that the products are fed in safely and that the cutting results are perfect with minimal leftovers and give-away.

Another plus point: For plastic-free slicing, customers can use innovative developments such as the MULTIVAC Sustainable Liquid Interleaver (SLI) instead of the commercially available separating film and thus further reduce plastic consumption during packaging.

Maximum process reliability and intuitive ease of use

The SLX 2000 can be used both as a stand-alone device and as a module within fully automatic cutting and packaging lines. Seamless integration into the MULTIVAC Line Control (MLC) enables particularly efficient machine and system operation, including line-wide start-up, starting, stopping, idling and recipe changes. Downtimes for recipe or format changes are reduced to a necessary minimum. At the same time, the IPC control with HMI 3 simplifies operation, reduces operating errors and at the same time ensures safe and reproducible processes.

As a future-proof model of the latest generation, the new slicer is also prepared for the use of MULTIVAC Smart Services and thus allows processes to be monitored, controlled and optimized in real time. In addition, the SLX 2000 also allows remote maintenance via MULTIVAC Remote Assistance (VPN and live support).

Maximum flexibility, high availability and MULTIVAC Hygienic Design

Short setup times, quick changeover options and full machine accessibility for easy maintenance and cleaning guarantee high availability in everyday production. Since the SLX 2000 is based on the MULTIVAC Hygiene Design, it meets the highest hygiene requirements of the food industry.

Loading, slicing, inserting, packaging and labeling of sliced goods - all from a single source

The SLX 2000 marks the start of the line, which can be seen in demo operation at the interpack in Düsseldorf on the main MULTIVAC stand. In conjunction with the RX 4.0 thermoforming packaging machine and other components from MULTIVAC, a line concept has been created here that stands out characterized by high performance, pack quality, process reliability, ease of use as well as future viability and digitization.

The product logs are automatically transported into the slicer, fixed there by the product grippers and then fed to the cutting area. A flexible cutting process enables a wide variety of portion sizes and shapes, which are guided via a checkweigher and, if classified as incorrect, ejected on the following rocker. The correct portions, on the other hand, are arranged on a horizontal automatic belt feeder according to the format of the packaging machine, lined up, buffered and inserted into the pack cavities of the RX 4.0 synchronously with the feed. "We achieve extremely high insertion accuracy thanks to the optimally coordinated line concept with track-centred loading and cutting and the consistent product flow," explains Julian Rieblinger, Product Manager of the Slicing Business Unit at MULTIVAC.

The packs are then sealed under a MAP atmosphere, cut and transported away. The labeling is carried out by the DP 230 direct web printer, which is equipped with a high-performance TTO 30 thermal transfer printer in the area of the upper web infeed. In addition, there is the option of printing the BBD on the upper web and applying a label to the upper and lower web.

A recyclable rigid film made of Mono-APET will be used as the bottom film at the trade fair. The top film is a sustainable, recyclable soft film made from PET.

Economical, efficient and sustainable at the same time

"Especially with this thermoforming packaging line, we are setting a clear example in the area of packaging and processing," says Rieblinger. “The SLX 2000/RX 4.0 combination is currently the most flexible and quickest to convert line in this performance class on the market. The performance is by no means at the expense of the quality. On the contrary: during the conception, our focus was primarily on product-friendly transport and product-friendly insertion of the portions, despite the high output. After all, we process food whose ecological footprint is far higher than the footprint of the packaging.”

At the interpack, the new slicer can also be seen in live operation in an outdoor area in front of Hall 4.

About MULTIVAC

Bundled expertise, innovative cutting-edge technology and strong brands under one roof: MULTIVAC offers complete solutions for the packaging and processing of food, medical and pharmaceutical products as well as industrial goods - and as a technology leader, it keeps setting new standards in the market. For more than 60 years, the name has stood for stability and values, innovation and sustainability, quality and excellent service. Founded in Allgäu in 1961, MULTIVAC is now a globally active solution provider that supports small and medium-sized companies as well as large corporations in making production processes efficient and resource-saving. The portfolio of the MULTIVAC Group includes different packaging technologies, automation solutions, labeling and inspection systems and, last but not least, packaging materials. The range is supplemented by needs-based processing solutions - from slicing and portioning to baked goods technology. The solutions are tailored to individual customer requirements in training and application centers. Around 7.000 MULTIVAC employees in more than 80 subsidiaries worldwide stand for real customer proximity and maximum customer satisfaction, from the initial idea to after-sales service. More information at: www.multivac.com