Handtmann shows solutions for pet food production

Handtmann in Biberach offers a variety of modular and flexible production solutions for the manufacture of pet food. Their core functions are filling and portioning, cutting/dividing, shaping, dosing or coextruding a wide variety of product masses. The production of shaped products and treats as cubes, bars, pellets, balls, hearts and more, but also the dosing of wet food or BARF in bowls, cans and cups is possible in addition to the production of twisted pet food sausages. The outstanding feature of all systems is the exceptional portioning accuracy thanks to the vane cell conveyor in the basic machine, the vacuum filler. This weight accuracy significantly reduces costs, especially when processing high-quality products.

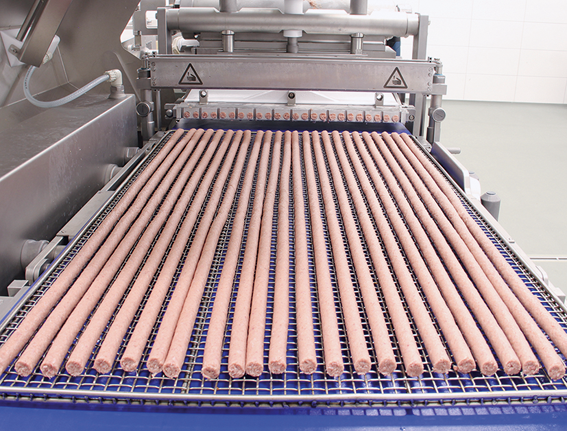

The range of Handtmann form systems is one of the production solutions that Handtmann is presenting at the interzoo in Nuremberg. Above all, it is characterized by the flexible use in many areas of application, from soft mass consistencies to solid masses. In addition, a large variety of shapes is possible with countless options, such as round, square, oblong, 3D shapes in the shape of a dog bone and more. The FS 510 forming system with a 24-fold filling flow divider, ie in a simulated 24-lane production, will be demonstrated at the exhibition stand with a substitute mass. Here the filling material is fed from the VF 800 vacuum filler to the filling flow divider. The filling flow divider with servo drive ensures an exact speed of the rotors in the filling flow divider. There is a constant product flow without pressure fluctuations and thus precise final weights. The filling flow divider ejects the filling material into multi-lane filling flows via format parts. The desired product shape is created with shaped tubes at the outlet. Changing the mold is quick and easy by exchanging the mold tubes. The products are separated directly at the outlet either with a wire or knife, without interruption linearly with the product speed. Production is possible on grids and sheets as well as conveyor belts. The visualization of the product shape and the calculation of the process parameters is very easy to do via the control of the vacuum filler.

A dosing solution that is flexible for small and medium-sized companies or serially suitable for the industrial production of pet food is the 85-3 dosing valve, which will be shown at the trade fair stand in combination with a smaller VF 608 plus vacuum filler. In addition to the very high quality and hygiene standards that are standardized for Handtmann (the ejector pistons are made of FDA-compliant, detectable material), the dosing valve offers several functionalities. On the one hand, the ejection speed of the dosing piston can be regulated and, on the other hand, a double-stroke function can be used. In addition, there is the option of using 3 different ejector pistons, including two variants with an additional cutting function, which also allows extremely sensitive products to be dosed gently. Thanks to the vane cell conveyor system in the vacuum fillers, even very liquid or hot products or products with inserts and large pieces can be gently dosed with a high weight accuracy.

All Handtmann systems are modular and can be flexibly integrated into complex overall processes. Safe synchronization is carried out here by the monitor control in the Handtmann vacuum filling machines. www.handtmann.de

Handtmann Hall 8 Stand 8-110.