Efficient solutions required at Anuga FoodTec 2022

Faster, more flexible, more sustainable - the food industry is facing numerous challenges and is making efforts to produce in a more resource-efficient manner. Renewable energies and their decentralized generation provide additional dynamics. Modern photovoltaic systems and combined heat and power plants for the combined generation of electricity, heat and cold help companies save on operating costs and CO2 emissions. However, the energy transition poses major challenges for the industry. While climate policy goals are becoming more and more demanding, efficiency regulation at EU level is also constantly evolving.

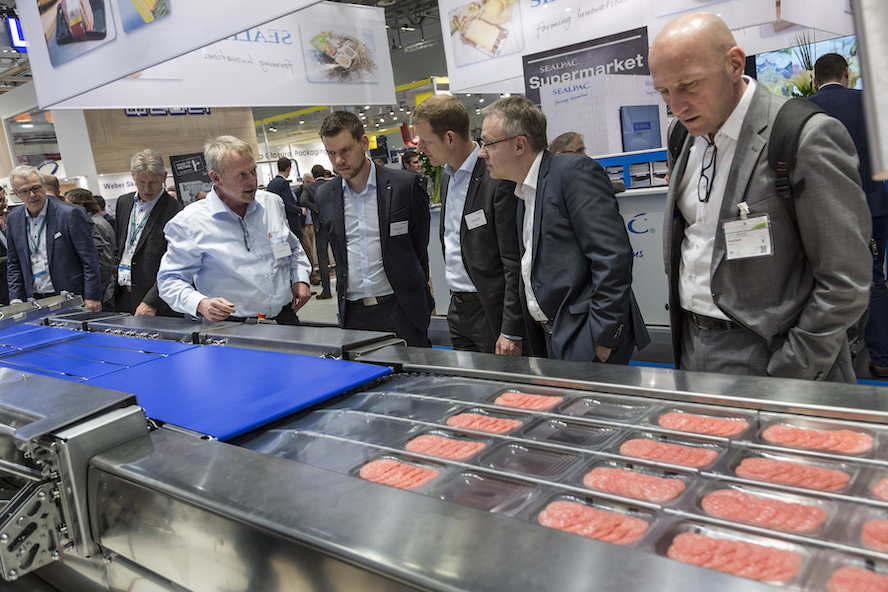

Food producers who want to guarantee their security of supply in compliance with legal regulations will find innovations at Anuga FoodTec from April 26 to 29, 2022 with which they can reorganize their energy efficiency. This shows that energy considerations are increasingly being taken into account as early as the design of the machines and systems - and all innovations are always linked to the aspects of digitization.

Maximum efficiency in the drive train

An important factor are compact electrical and pneumatic components that are trimmed specifically for higher productivity with reduced energy consumption. In March 2021, the new Ecodesign Directive came into force across Europe. As a result, the standard asynchronous motors designed for continuous operation also had to be further developed. Frequency converters also fall within the scope of the new regulation for the first time. Drive specialists already offer a comprehensive portfolio of electric motors that meet the more demanding requirements of efficiency class IE4. To ensure that the switch to the new engines is successful, they provide their OEM partners and end customers with web-based tools.

The drive train as an electromechanical overall package is the conceptual prerequisite for an energy-efficient integration of the individual components - depending on the machine type and the specific requirements, 20 to 50 percent energy can be saved. Decentralized synchronous servo drives have an advantage here over asynchronous motors. The weight also plays a role here, because the lighter a servo motor is, the less drive power it requires. A savings effect that quickly adds up in high-performance packaging machines with 50 or more servo axes. At the same time, more and more assemblies such as compressed air valves are moving from the control cabinet directly into the machines. Fewer lines, shorter hoses and a lower risk of leakage are the result of this decentralization strategy of the plant manufacturers.

Big data against wasting energy

In addition to efficient electric motors and pumps as well as methods for energy recovery, demand-controlled use of energy is increasingly becoming the focus of food production. Digitization makes it possible to identify additional savings potential. In the future, big data and self-learning algorithms will create a comprehensive image of all energy flows in the company, right down to the heating, air conditioning and ventilation systems. Taking into account forecast data for production, building use and the weather, a simulation of the total energy turnover is carried out, with cost minimization and CO2 savings being specified as goals. Such a system does not react to the actual status, but controls the energetic processes in a foresighted manner according to the calculated forecasts of the electricity, heating and cooling requirements.

Intelligent and robust sensors that collect data, generate information and communicate this in real time are the basis for such a networked energy management 4.0. They record energy consumption and basic electrical quantities. Mobile apps make it possible to evaluate the energy data regardless of location. They record heat, electricity or compressed air consumption down to the level of the individual machines and evaluate them in clear management interfaces. Through a structured collection of data from various sources, key performance indicators can be calculated and compared directly, both for entire systems and for individual consumers. The way the data is displayed can be customized. The machine operator can keep an eye on the current system status, while the plant manager is interested in energy consumption and production statistics.

Sector coupling as a new scenario

Such big data technologies also play a key role for the success of the energy transition beyond the company level. At the Institute for New Energy Systems at the Technical University of Ingolstadt, Prof. Dr.-Ing. In the "BlueMilk" project, Uwe Holzhammer is therefore specifically identifying opportunities for companies to actively help shape the energy transition. "The goal must be to cover the residual electricity demand in the future using renewable energies from wind and photovoltaics," he affirms. Together with partners from the dairy industry, Holzhammer and his team are investigating where fossil heat can be substituted in dairies through sector coupling and the use of renewable electricity, and where there is still potential for increasing energy efficiency in production.

At the same time, the scientists want to show ways of obtaining and/or providing energy flexibly. One approach to sector coupling that "BlueMilk" is investigating is intelligent combined heat and power using combined heat and power plants. "Organizing the feed-in into the general supply system depending on the electricity price opens up new opportunities for dairies not only to generate revenue but also to reduce CO2 emissions," explains Volker Selleneit, a research associate in the team.

While the exhibitors at Anuga FoodTec can respond to visitors' questions in all product segments with solution approaches, experts will also show in the event and congress program of the trade fair which measures and ideas the food industry can use to tackle the challenges of the energy transition and the desired resource conservation.

Booth: MULTIVAC, Process Technology, Hall 9

Further information, list of exhibitors and event and congress program: www.anugafoodtec.de