Handtmann presents the latest technology and food innovations at AnugaFT

Handtmann presents numerous innovations for the production of a wide range of food products and pet food. Process solutions from product preparation to handover into the packaging solution for start-ups, trades, medium-sized businesses and industry. On top of that, FOOD INNOVATION and exciting concept products attract people to the Handtmann show kitchen!

New molding systems FS 501 and FS 503 for craft and medium performance segments

The new, single-lane forming system FS 503, in combination with a Handtmann vacuum filler, enables the fully automatic production of freely shaped 3D products with a diameter of up to 100 mm. Almost all 3D product shapes and geometries are possible. Optionally, a height-adjustable flattening belt can be used for flattened products with a product height of 10 – 55 mm, such as burgers, patties and thalers. Handtmann now offers the new one for food service, gastronomy, lunch, catering and sales counters Forming system FS 501 a flexible solution that can be easily integrated into daily production. The attachment is connected directly to the Handtmann vacuum filler and is flexible for processing a wide range of product masses and products as if they were handmade. Examples are dumplings of all kinds, such as potato dumplings, bread dumplings and vegetable dumplings or soup ingredients from sausage dumplings to semolina dumplings and liver dumplings. But marzipan balls and other doughs and desserts are also optimally shaped.

|

|

| Forming system FS 503 | Forming system FS 501 |

New Handtmann molding and co-extrusion system FS 525 KOEX for filled products

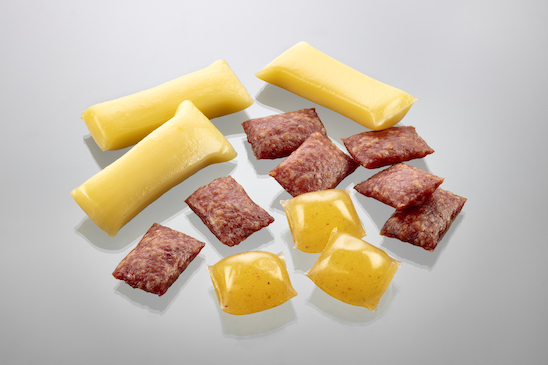

The Biberach-based company will be presenting numerous solutions for molded products at the trade fair stand to interested parties with a focus on the ongoing trends of snacking and convenience. The FS 525 forming and cutting system, which combines two different forming principles for maximum flexibility in industrial applications (perforated plate forming technology for freely shaped 3D products and rotary cutter for different cross-sections with smooth cutting), now also offers the option of co-extrusion. This further expands the scope of application to produce filled molded products with closed or open ends in a caliber of 20-50 mm. Thanks to servo technology, the positioning of the filling is always accurate and exact, whether pasty, chunky or soft. Simple operation, quick setup as well as assembly and disassembly allow a wide range of products with quick product changes. A single-lane production output of up to 150 portions per minute is possible. The FS 525 forming and cutting system can be perfectly integrated into holistic processes, such as the Handtmann transfer system, or synchronized with automation options such as weighing systems, tray loading or insertion into deep-drawing machines.

|

| New Handtmann molding and co-extrusion system FS 525 KOEX for filled products |

New flexible dosing systems for a wide range of products directly into the packaging

In the dosing segment, too, numerous solutions from start-ups and craft applications to multi-lane system solutions for fully automated industrial production will be demonstrated live at the trade fair stand. The new dosing systems DS 554 and DS 560 P will be presented to the public for the first time multi-lane model DS 560 P offers high line performance in the dosing of liquid, low-viscosity, high-viscosity, pasty, inhomogeneous and coarse filling materials, especially with coordinated interfaces to packaging machines. The intuitively easy-to-use servo-controlled lifting and lowering device in combination with servo-driven filling flow technology with integrated cutting function in the valves ensures drip-free and weight-accurate dosing. Thanks to the high flexibility of Handtmann valve technology with its unique selling point, very different filling masses and portion sizes can be produced in just a few steps. This saves time and costs and enables the permanent expansion of the product range in order to be able to react to trends in the market. The Single-track and flexible dosing system DS 554 shows its strength particularly in the exact gram dosage of lumpy, fibrous and inhomogeneous filling products. In addition to high variability and interface capability, innovative valve technology and intrinsic safety, both new systems are characterized by easy operation via the control panel of the vacuum filling machine.

|

| New flexible dosing systems for a wide range of products directly into the packaging |

Novelty and trade fair highlight ConProSachet system wins IFTA 2024 gold

The absolute highlight of the trade fair is the Handtmann ConProSachet system. It offers start-ups as well as medium-sized and industrial companies a process for packaging pasty foods and nutritional supplements in bags made from seaweed-based material in the form of sachets, pods and pockets. Catering and food service with out-of-home consumption, snacking as well as convenience and ready meals in particular benefit from the new process. The material is obtained from seaweed and is an ecological and biodegradable raw material. The most significant advantage is that the bags are edible - meaning they can simply be consumed - or can be disposed of in organic waste after use, as they biodegrade within a few weeks. The ConProSachet system was awarded the International FoodTec Award (IFTA) 2024 Gold as a pioneering process, which was developed in coordination with Notpla, a British innovative materials company and winner of the Earthshot Prize for environmental innovation.

|

|

| Handtmann ConProSachet system | Food Innovation: ConPoSachets |

New automation modules for product handling

In the product handling segment, Handtmann is presenting new automation modules for freshly manufactured products for the first time. The Underlay tape UB 365 enables the combination of several optional work functions in the smallest possible space: aligning, placing paper underneath and stacking. All work functions are integrated into the central control concept, whereby existing product data is adopted and newly recorded information is played back. For example, shape deviations recorded by the UB 365 can be passed on to a successor system as a rejection criterion via Handtmann Line Control. The alignment function enables precise positioning of the products for the subsequent work functions and thereby ensures a high level of process stability. The UB 365 enables a continuous feed of product documents, the length of which can be individually adjusted depending on the product size. Various materials in different widths can be used as a product base. Optionally, the products can then be stacked in order to package them as resource-efficiently as possible or to transfer them to a process belt (e.g. freezer). The ES 388 insertion system is designed for minced meat portions and other minced products such as ribburgers and cevapcici with an insertion rate of up to 90 portions per minute in tray packaging. Tool changes and shell changes in seconds as well as central and networked control of the entire system using Handtmann Line Control with central program switching for the entire line bring a high level of rationalization. In conjunction with the Handtmann minced meat line, a perfectly coordinated overall solution from the filling and portioning process to the packaging solution.

New sausage filling lines PVLH 251 L and PVLH 252 L for high-performance production

The new PVLH 252 L sausage filling line for industrial sausage production will be exhibited for the first time at Anuga FoodTec. The PVLH 252 L is the mirrored version of the PVLH 251 L (long version). Both versions offer medium-sized and industrial sausage manufacturers an automated production process for portioning, twisting and hanging boiled sausages in peeling and collagen casings. Vegan/vegetarian products and meat substitute products can also be automatically produced in shirred plant-based casings. Sausage products from the pet food segment can also be produced. The high-performance line shows its strengths primarily in classic hot dog production and with minimal product changes.

|

| New sausage filling lines PVLH 251 L and PVLH 252 L for high-performance production |

New Handtmann Inotec Wolf IW for universal shredding

In the area of product preparation, the new Handtmann Inotec Wolf from the IW series for the production of meat products and pet food will be presented to the international trade fair audience for the first time. Typical applications in the area of meat and sausage products or meat alternatives are salami, minced meat and boiled sausage as well as fine meat products - and in pet food wet food, sticks and bites as well as chunks in gravy. The three available models are designed for medium to high industrial production with an output of up to 9 tons per hour in continuous operation. Both deep-frozen blocks down to -20° Celsius and fresh raw materials are shredded reliably and gently without changing the cutting set. If special applications are required, a wide range of knives and end hole discs are available. With a hopper volume of 550 or 670 liters, the grinders in the IW series have a generously dimensioned product reserve and can be fed using an automated belt feed or lifting and tilting device. The new IW grinders can be integrated into the Handtmann Inotec line control and safety circuitry as an integral part of automated process lines.

|

| New Handtmann Inotec Wolf IW for universal shredding |

In addition to numerous process-supporting Industry 4.0 solutions, the filling and portioning specialist from Biberach is also on site with its Handtmann Customized Solutions, with which the company offers tailor-made solutions for individual customer requirements. Trade fair visitors can look forward to the new FOOD INNOVATIONS from Handtmann. In addition to the sachets made from alginate casing, numerous new concept products and product ideas will be available for tasting.

About Handtmann filling and portioning systems (F&P)

The Handtmann F&P division is part of the owner-managed Handtmann group of companies based in Biberach in southern Germany. It is a leading manufacturer of process technology for processing food and offers modular and cross-process line solutions from product preparation to packaging solutions. The offer is flanked by in-house developed, process-supporting digital solutions. At the same time, investments are made in sustainable concepts for food innovation. This also includes the state-of-the-art technology and customer centers at the company headquarters. The Handtmann Group employs around 4.300 people worldwide, including around 1.500 at F&P. With numerous subsidiaries and sales and service partners, the company is represented globally in over 100 countries and is also networked across the board through strategic partnerships. www.handtmann.de/food